I vantaggi dell’Elettroerosione per il settore automobilistico: La scommessa del principale produttore di veicoli elettrici su ONA.

\ I vantaggi dell’Elettroerosione per il settore automobilistico

The automotive sector is going through changing times with the introduction of electric vehicles. ONA’s technology is a major contender in this sector thanks to all the competitive advantages that our machines provide to these manufacturers’ production processes. A clear example of this is the trust that the world’s leading electric vehicle manufacturer has placed in ONA with the purchase of two of our units: the AV130 wire EDM model and the first ONA IRIS T10 machine that we introduced onto the market.

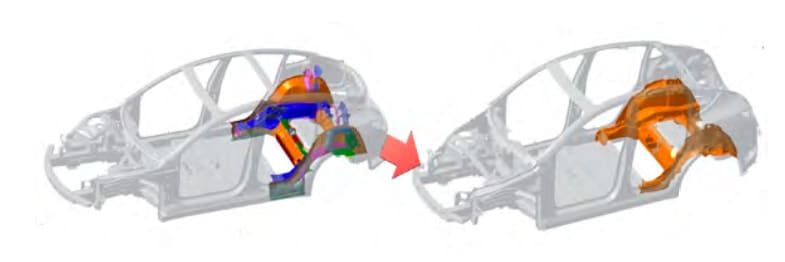

This leading electric vehicle automotive company is one of the key drivers of the world’s transition towards sustainability in the sector thanks to its electric cars. During this process of change, the manufacturer has changed its way of producing. Its goal is to optimise its manufacturing process, reducing the number of parts necessary to manufacture the bodies of its cars. “This new car body production system reduces production time, operation costs, manufacturing costs, factory size and, consequently, its operating costs. Tool and equipment costs are even reduced”, the company says.

Stepping up to help them meet this goal is ONA and its models of large-scale machines, including the ONA AV130 and ONA IRIS T10. “We manufacture the larges scale wedm and die-sinking machines of the market.” We offer unprecedented flexibility to adapt each unit to each customer’s individual needs thanks to its modular design. In addition, the ability to incorporate a dual head into the machine reduces production time in half, increasing production process profitability enormously.

ONA IRIS T10: Double head for the most advanced die-sinking EDM machine.

This customer has been the first to incorporate one of the new ONA IRIS model units into its facilities, benefiting from the most advanced technology on a die-sinking EDM machine.

Earning the trust of a manufacturer as important as this one was based on three key points:

- First, the ONA IRIS machine has a simple, intuitive, and easy-to-use interface with a large number of digital tools incorporated to simplify handling for any user.

- Second, it has a powerful graphics engine. The user can create all of the simulations it needs to test possible results before launching the project. This way, the user has absolute control over the manufacturing process, easily making changes until the desired result is obtained. And all of this while the ONA IRIS machine is in full production with another project.

- Lastly, the ONA IRIS machine integrates the market’s most powerful generator, that is 100% digital, configurable, and programmable. This high-performance, smart digital generator can reach 400 Amperes of intensity, the most power on the market. More power means more productivity.

On top all this are the advantages that double head machines provide production processes. The incorporation of a second head controlled by independent CNCs to the ONA IRIS model makes the unit acquired by the sustainable car manufacturer a highly profitable solution: 50% savings on erosion time and up to 200% productivity.

ONA AV130: The largest wire EDM machine on the market.

The automotive company also acquired our new ONA AV130 model, the market’s largest wire EDM machine. With mechanics designed to provide maximum performance for pieces weighing up to 10 tonnes, the AV130 model provides results with excellent reliability, even working autonomously. In addition, our 100% ecological filter without added waste and negligible maintenance costs is entirely aligned with their eco-design and sustainability philosophy. With this, the world’s first 100% ecological filtration system, ONA is providing one of the most economical and environmentally-friendly solutions on the market.

The goal of getting more profit out of the body manufacturing process is met thanks in part to ONA and all of the possibilities our machines provide. We are experts in EDM, demonstrated by our innovative technology.

Main application: Production of very large aluminum casting molds.